Transfer Concrete Slab Steel Plate Lifting Overhead Bridge Crane Clamp

Product Details and Features

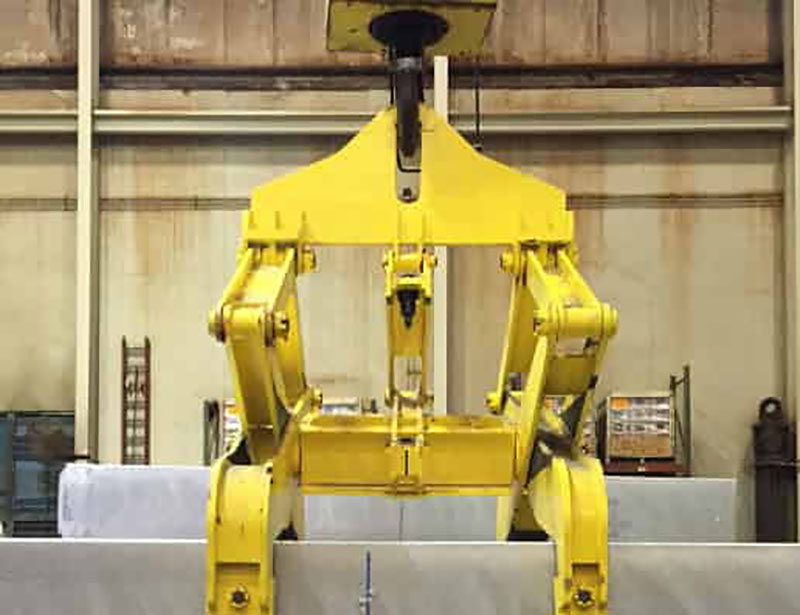

Crane clamp is a clamp used for clamping, fastening or hoisting. It is mostly used in conjunction with bridge cranes or gantry cranes, and is widely used in metallurgy, transportation, railways, ports and other industries.

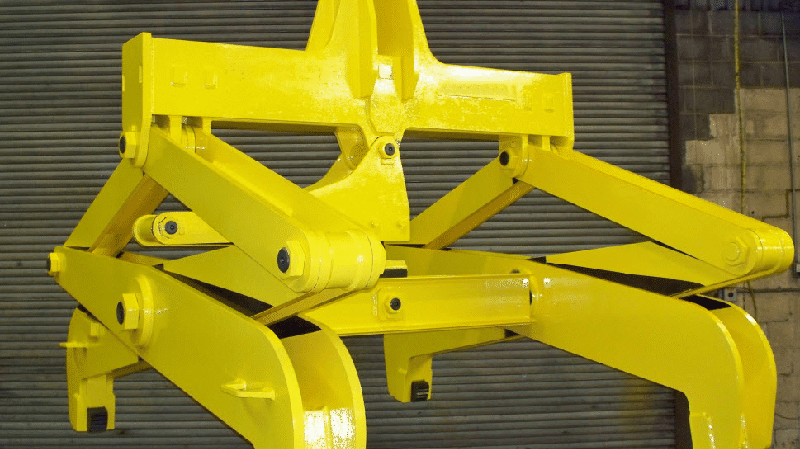

The crane clamp is mainly composed of seven parts: hanging beam, connecting plate, opening and closing mechanism, synchronizer, clamp arm, support plate and clamp teeth. Clamps can be divided into non-power opening and closing clamps and power opening and closing clamps according to whether additional power is used.

Application

The power crane clamp is powered by the opening and closing motor, which can work automatically without the need for ground workers to cooperate with the operation. The work efficiency is relatively high, and various sensors can also be added to detect the clamp state.

SEVENCRANE crane clamps are designed and produced in strict accordance with the requirements of safety regulations, and the products have a production quality certificate, which meets the requirements of most scenarios.

The crane clamp material is forged from 20 high-quality carbon steel or special materials such as DG20Mn and DG34CrMo. All new clamps are subjected to a load test, and the clamps are checked for cracks or deformation, corrosion and wear, and they are not allowed to leave the factory until they pass all tests.

Crane clamps that pass the inspection will have a factory qualified mark, including rated lifting weight, factory name, inspection mark, production number, etc.

Product Process

The non-power opening and closing clamp structure is relatively simple, the weight is relatively light, and the cost is low; because there is no power device, no additional power supply system is required, so it can clamp high-temperature slabs.

However, because there is no power system, it cannot work automatically. It needs ground workers to cooperate with the operation, and the work efficiency is low. There is no indication device for the opening of the clamp and the thickness of the slab.The opening and closing motor of the power clamp is powered by the cable reel on the trolley.

The cable reel is driven by a clockwork spring, which ensures that the cable is completely synchronized with the lifting and lowering of the clamping device.