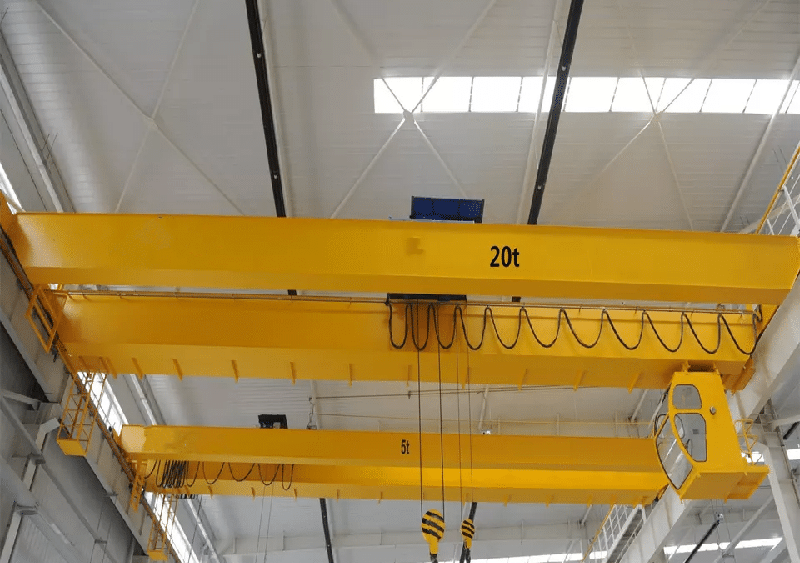

50 Ton Electric Double Girder Eot Crane Manufacturers

Product Details and Features

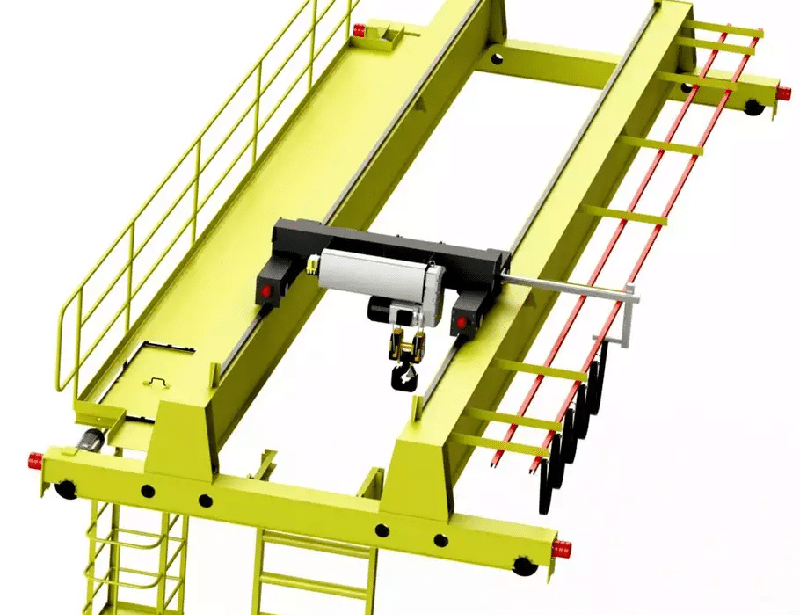

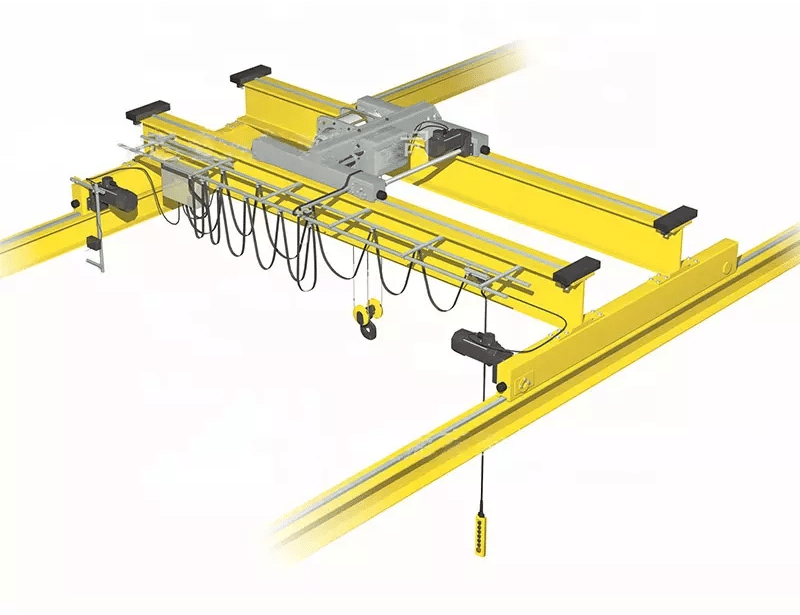

About EOT Cranes This is a kind of lightweight lifting equipment of our company, it includes two types, one is the double girder EOT Crane, and another is single girder EOT Crane, and these two types electric bridge cranes are best-customized equipment for lifting, every custom-made requirement you have is going to be met well, as soon as you get connected to us. The two free-torsion box-grinders built in the Double Girder Crane equipped an overhead crane for lifting and carrying heavier loads compared with Single Girder/Single Girder Overhead Crane. Using current calculation systems, SEVENCRANE double girder overhead crane can adjust its weight in order to minimize forces applied on the structure by the loads, improving stability in lifting machinery during loading large volumes of goods. SEVENCRANE Double Girder Crane reduced the weight on wheels, saving costs for new supporting structures, and increased lifting capability of existing structures.

Application

Double girder EOT cranes may be provided to meet Class A, B, C, D, and E of the CMAA, with typical capacities of up to 500 tons, with reaches of 200 feet and longer. Double-girder top running cranes are composed of two bridge beams attached to the track, and are generally provided with electric wire-rope top-running hoists, but may also be provided with top-running electrical chain hoists depending on the application. Because the hoists can be placed between or above the bridge girders, an additional 18-36 of sling height can be obtained using double girder bridge cranes. Double-girder cranes typically need a higher clearance above the cranes beam-level height, as the hoist cart rides atop the cranes bridge beam.

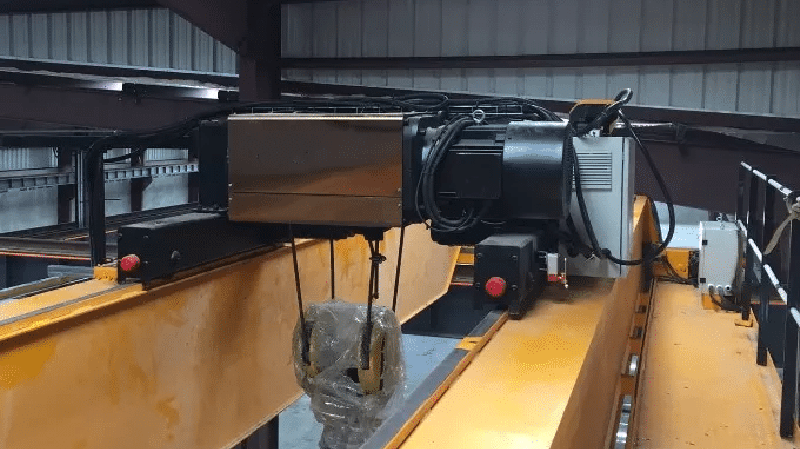

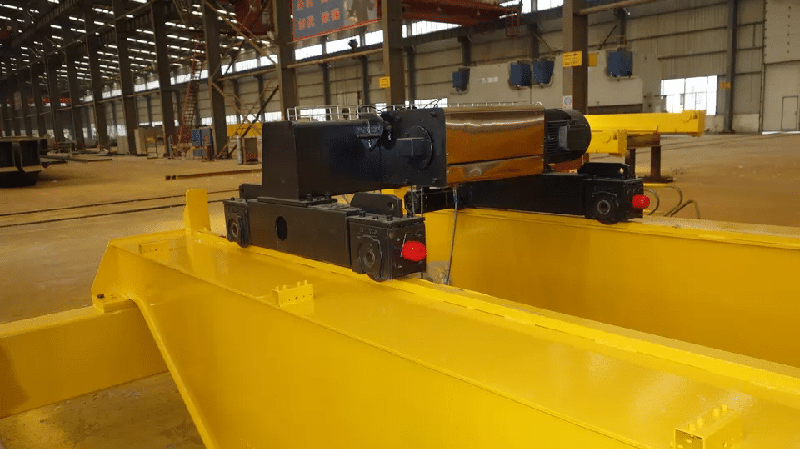

Product Process

Double girder cranes are typically used when duty requirements are D+ (Very Heavy Duty) or E (Extreme Duty) because special hoisting equipment typically includes a open hoist that has its own split-case gearbox, a heavy-duty motor, and brakes mounted to a bridge structure. Hook-mounted double-girder travel-overhead cranes, which use hooks as their hauling devices, are commonly used in machine shops, warehouses, and loading yards for general lift applications. Bridge-running mechanisms Two independent driving systems are used for driving a travelling crane individually.