Electric Double Girder Overhead Crane For Workshop

Product Details and Features

Electric overhead cranes are available in four basic configurations, adapted to a variety of work conditions and lifting requirements, including single-girder, double-girder, overhead-traveling, and stowage-under-hanging systems. Horizontal travelling for a push-type crane is powered by operator hand; alternatively, electric overhead crane is powered by electrical energy. Electric overhead cranes are electrically operated either from a control pendant, a wireless remote, or from an enclosure attached to the crane.

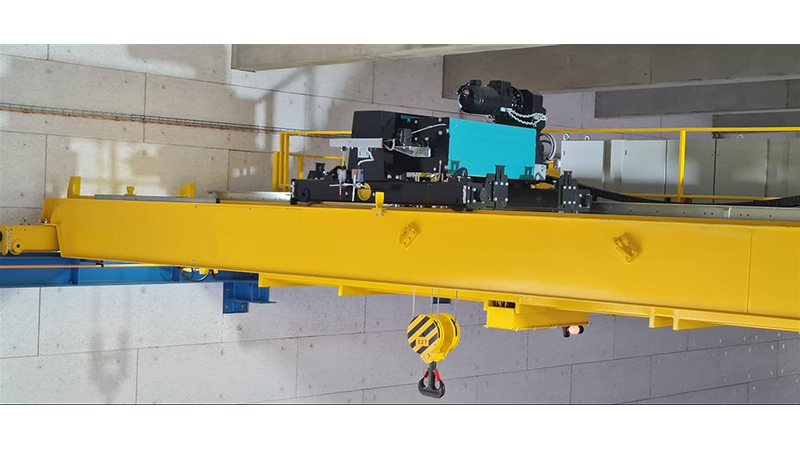

Not all overhead cranes are created equal, there are some standard features of overhead cranes, such as the hoist, the sling, the beam, the bracket, and the control system. Generally, Box Girder Cranes are used in pairs, the hoisting mechanisms operating on tracks attached at the top of each Box Girder. They are composed of parallel tracks, very similar to rails of a railway, with the traverse bridge traversing a gap.

It is also known as the deck crane, since it is composed of parallel runways connected by a travelling bridge. Single-girder electric-trunnion-type cranes are composed of electric trunnions that travel along a lower flange on a main girder. Double girder electric overhead crane has a crab-moving mechanism, moving on top of two of the main girders.

This bridge beam, or a single girder, supports the lift mechanism, or the hoist, which runs along the lower rails of the bridge beam; it is also called a below-ground or below-hanging crane. A bridge crane has two overhead beams with a running surface connected to a buildings supporting structure. An overhead bridge crane will almost always have one lift that moves to the left or the right. A lot of times, these cranes will also be running on tracks, so that the entire system can travel through a building either front-to-back.

Application

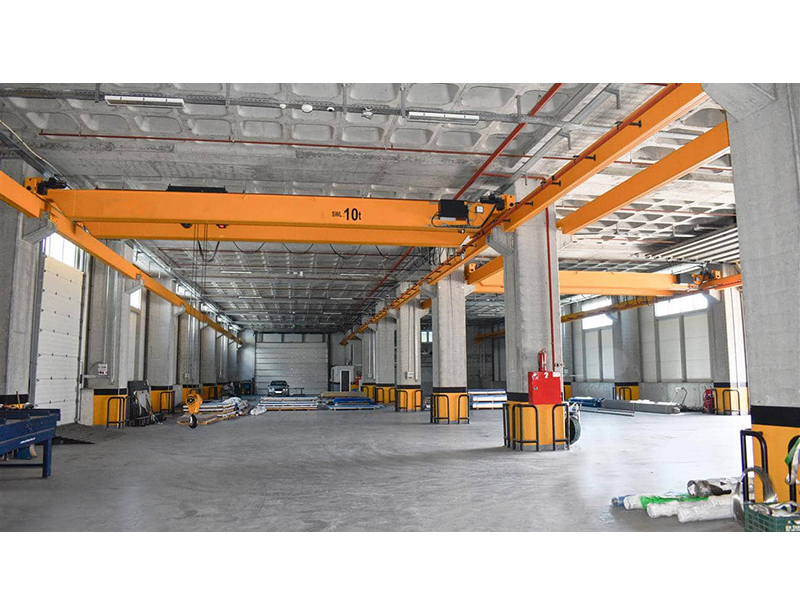

The crane mechanisms are used to transfer a heavy or large load from one location to another, reducing the human force, thereby providing higher production rates and efficiency. An overhead hoist lifts and lowers a load using a drum or hoist wheel, which has chains or wire rope wrapped around it. Also called bridge cranes or electric overhead cranes, overhead factory cranes are ideal for the lift and movement of goods in manufacturing, assembly, or logistics operations. A double-girder overhead travelling crane is perfect for lifting and moving especially heavy loads up to 120 tonnes. It impresses by its wide spanning area up to 40 meters, and it can be equipped with further features depending on requirements, like a service walkover in the bridge section of the crane, an arm-crabber with maintenance platforms, or an extra lift.

Product Process

Electric power is more often than not transferred from the stationary source to a moving crane deck via the conductor bar system mounted on a beam on the track. This type of crane operates using either pneumatic air-powered systems or a specifically designed electrical explosion-proof system. Electric overhead cranes are generally used in production, warehouse, repair, and maintenance applications in order to maximise efficiency and work safety, and simplify the flow of your operations. Shipbuilding overhead cranes are specially designed to meet the requirements for space, and incorporate steel plate hoists and a variety of types of electric powered chain hoists.