LD Wireless Remote Control 5ton Industrial Overhead Crane

Product Details and Features

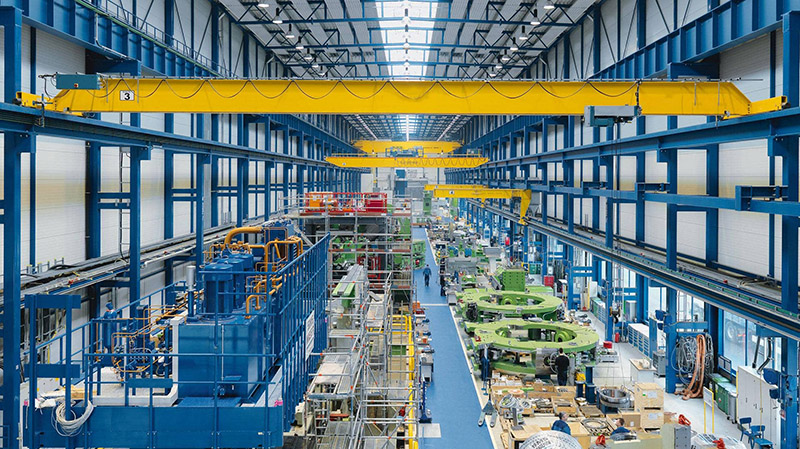

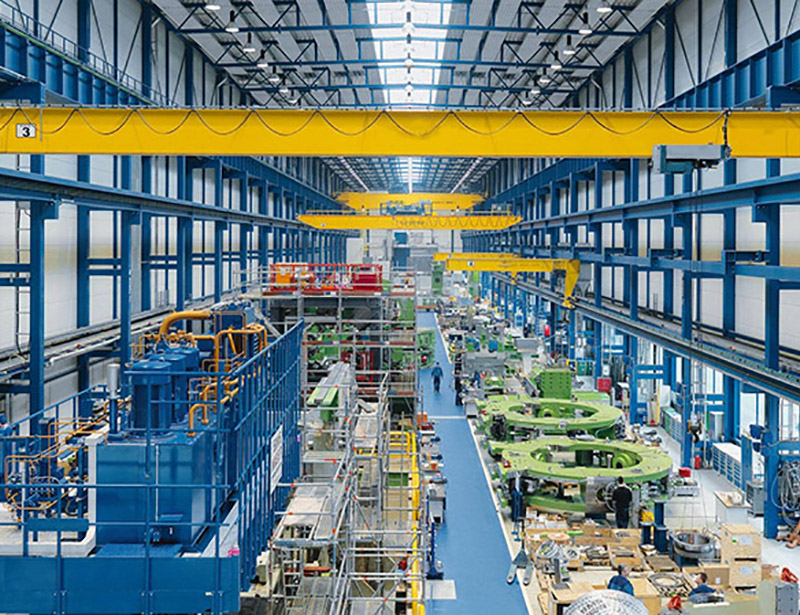

Industrial overhead cranes consists of one girder beam supported on each side by an end truck. The electric hoist is underhung–meaning they run on the bottom flange of the single girder. It is suitable for the workshop where there are column beams and runway beams. Industrial overhead cranes gets six directions of movement including forward and backward, left and right, up and down.

Application

Industrial overhead cranes can be used in many fields and industries to support handling and processing operations across the entire structure, including heavy manufacturing applications, steel plants, chemical plants, warehouses, scrap yards, etc. Industrial overhead cranes can be designed for general lifting purposes, and also special lifting applications. Industrial overhead cranes provide the highest lift capability of all materials handling solutions.

For example, almost all pulp mills using industrial overhead cranes to do the routine maintenance and lift heavy pressing rollers and other equipment; Industrial overhead cranes for automotive applications perform multiple functions ranging from materials handling and supply chain applications, to lift and haul applications.

SEVENCRANE designs, builds, and distributes a full range of material handling equipment, including Industrial overhead cranes, single or double girder, top-running overhead crane, underhung overhead cranes, or even custom-built cranes, safe working load from 35 pounds to 300 tons.

Product Process

Industrial overhead cranes increase the effectiveness and safety of operations at production or handling facilities, and they also optimize the work process. Industrial overhead cranes also improve performance, because it load and unload more quickly.

The efficiency of the industrial overhead cranes depends on how well it fits specific operations. When you need to move bulky materials or extremely heavy loads throughout your production space, using a Industrial overhead cranes are perfect for industrial settings.